Spotlight: Conveyor Automation at Sadler’s Smokehouse

About Sadler’s Smokehouse

Sadler’s Smokehouse is a family-owned manufacturer and marketer of branded and private-label meat and food products, headquartered in Henderson, Texas. Sadler’s authentic premium pit-smoked meats, side dishes, and other barbecue-related items are distributed nationwide through major grocery retailers, food service distributors, national chain restaurants, and other branded food processors. Founded in 1948 by Harold Sadler, the company motto still reflects Mr. Sadler’s founding belief that perfection takes time and there is no compromising delicious, slow-smoked flavor. In 2020, global branded food company Hormel Foods Corporation acquired Sadler’s Smokehouse for $270 million.

Business Need

Sadler’s Smokehouse was looking to improve automation, throughput, and reliability with its product labeling. Additionally, there was a need for automation to reduce personnel required to run lines as well as the overall labeling costs Specific business objectives included:

- Maintain label printing accuracy

- Improve label printing speed and production throughput

- Reduce personnel required to run lines through automation

- Reduce overall costs for labeling products

Solution – Conveyor Automation

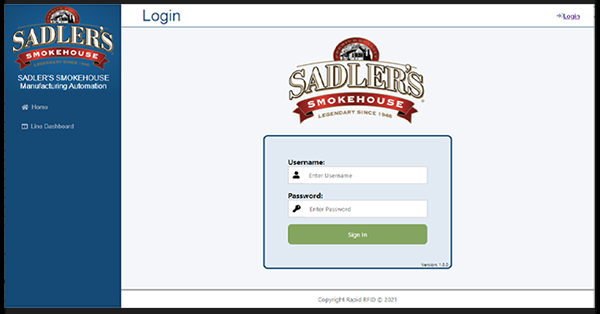

To achieve the desired throughput of 60 products per minute, Vertical Systems’ implemented their Conveyor Automation solution with customizations specific to Sadler’s Smokehouse. The use of scales, printers, label applications, and Vertical Systems’ workflow automation software helped optimize performance and reliability.

Digital tablets and kiosks allow Sadler’s Smokehouse team members to easily manage and monitor manufacturing jobs through dashboards and reports. All product activities (metal detection, weighing, labeling, etc.) are logged into a centralized database for reporting and integration with other systems.

Technology

- Bartender Label Printing

- Cognex Imagers (DataMan Software)

- Metal Detectors

- Rice Lake Weighing Systems – 1280 Indicators

- SATO print & apply labelers

- Vertical Systems Conveyor Automation

- Vertical Systems Workflow Automation Software

Results

Sadler’s Smokehouse has achieved visibility into its entire labeling process as products are validated, weighed, labeled, packed, and efficiently tracked as they are placed on and transported by pallets. Throughput has increased as they are boxing and labeling 60 products per minute. Costs have been lowered through a reduction of required personnel via automation and efficiencies gained through the automated labeling process.

Conclusion

Sadler’s Smokehouse improved automation, throughput, and reliability of products labeled through automated processes with the implementation of the Vertical Systems Conveyor Automation solution. Positive outcomes were achieved through reduced personnel, manufacturing efficiency, and a simplified management and reporting interface.

Vertical Systems is a software company with core offerings centered around RFID technologies. VSI’s RAPID RFID product suite offers a wide range of solutions to improve asset visibility and reduce labor costs.